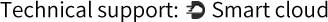

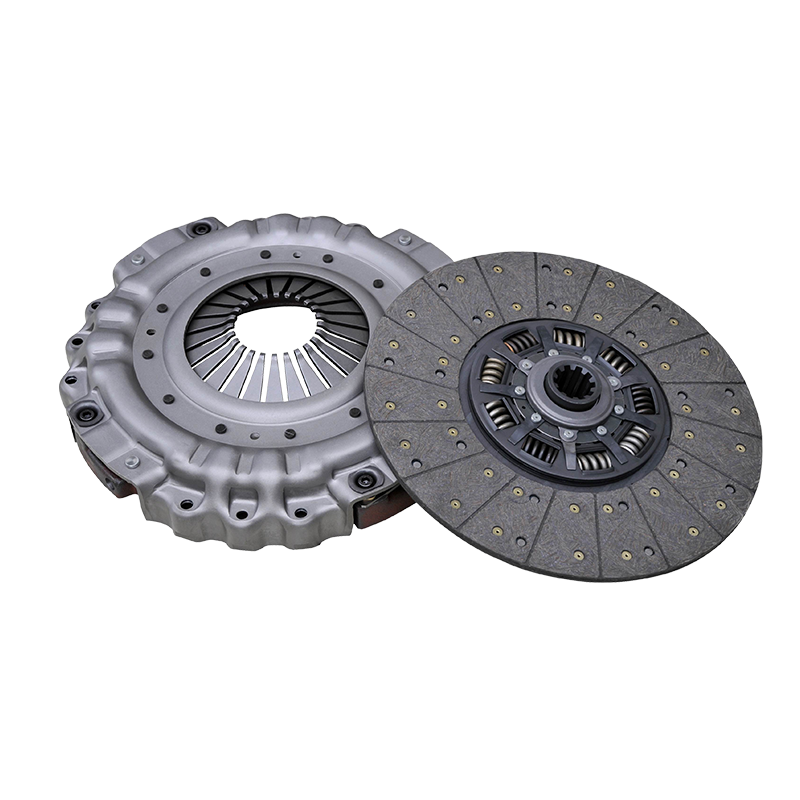

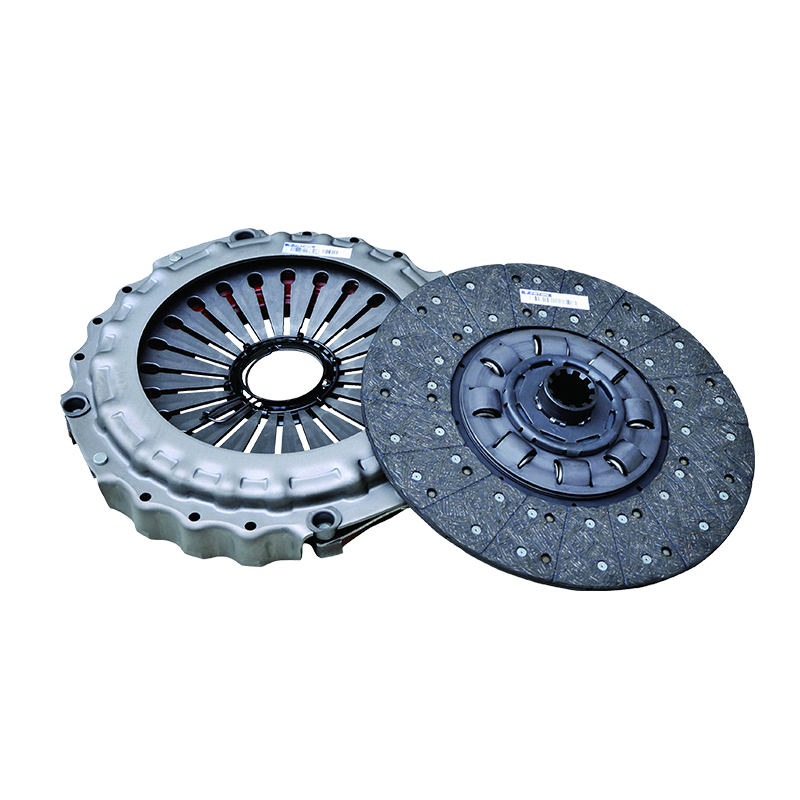

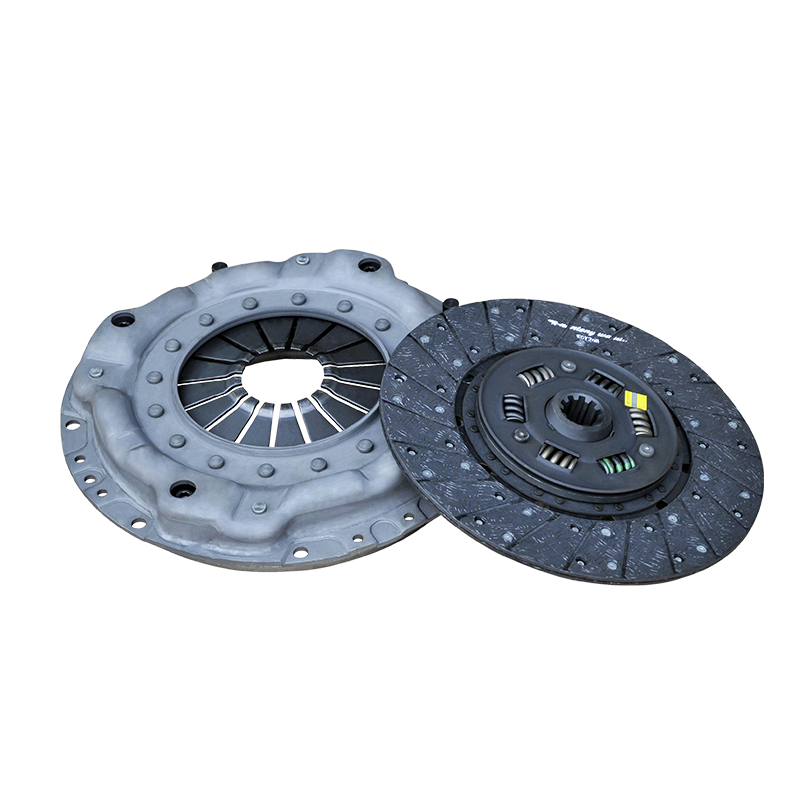

430 Ťahaný typ zostavy lamely poháňanej spojkou Výrobcovia

430 Potiahnite zostavu spojky

-

V náročnom svete komerčnej dopravy je spoľahlivosť každého komponentu prvoradá. Zostava spojky, k...

ČÍTAJTE VIAC -

Úvod: Kritické prepojenie v ťažkých hnacích jednotkách V zložitom ekosystéme komerčnej nákladn...

ČÍTAJTE VIAC -

Spoľahlivý prenos obrovského výkonu motora na hnacie ústrojenstvo je základnou požiadavkou každéh...

ČÍTAJTE VIAC -

V náročnom svete komerčnej nákladnej dopravy je prvoradá efektivita, spoľahlivosť a pohodlie vodi...

ČÍTAJTE VIAC -

Pre manažérov vozových parkov, vedúcich údržby a profesionálnych vodičov je vytrvalá snaha o efek...

ČÍTAJTE VIAC

Have the main components of the 430 pull-type clutch assembly been heat treated (such as ion carburizing heat treatment, carbonitriding, etc.)? What role do these processes play in improving clutch performance?

In our company, which focuses on the design, research and development, manufacturing and sales of heavy-duty vehicle clutches, we not only uphold the rigorous spirit of German technical standards, but also strive to integrate the concept of high-quality products into every production link. As a leader in the industry, we have adopted a variety of advanced manufacturing processes, including heat treatment, for clutch assemblies, especially the main components of the 430 pull-type clutch assembly, to ensure the excellent performance and long-term durability of the products.

Heat treatment is one of the key steps to improve the performance of metal parts. It changes the microstructure of the material, thereby enhancing its key performance indicators such as hardness, wear resistance, and fatigue resistance. In the manufacturing process of the 430 pull type driven plate, we pay special attention to the heat treatment of key components such as friction plate backing plate, pressure plate, release lever, etc., to ensure that they can withstand high-load operation under extreme working conditions.

Ion carburizing heat treatment is an advanced surface strengthening technology. By bombarding the surface of the workpiece with high-energy ion beams in a vacuum or inert gas environment, carbon is introduced to form an extremely hard and wear-resistant carbide layer. This treatment not only significantly improves the hardness of the component surface, but also enhances its corrosion resistance and wear resistance. For the friction plate backing plate of the 430 pull-type clutch pressure plate, ion carburizing heat treatment can effectively extend its service life and reduce the performance degradation caused by friction and wear.

Carbonitriding is a heat treatment process that simultaneously infiltrates carbon and nitrogen into the metal surface. It combines the advantages of carburizing and nitriding and can achieve a dual improvement in the surface hardness and wear resistance of the material at a lower temperature. For parts such as the clutch pressure plate and release lever that are subject to complex forces and require high strength and high toughness, carbonitriding treatment can optimize their microstructure and improve the overall mechanical properties, especially in terms of fatigue strength and impact toughness. The application of this process enables the 430 pull type driven plate assembly to maintain a more stable performance output and reduce the failure rate during frequent engagement and separation.

The effect of heat treatment on clutch performance

The significant increase in surface hardness of heat-treated main components, such as friction plate backing and pressure plate, directly enhances the wear resistance of the clutch. This means that under long-term and high-intensity use conditions, the clutch can resist wear more effectively, extend service life, reduce replacement frequency, and thus reduce maintenance costs for users.

Heat treatment processes such as carbonitriding significantly improve the fatigue strength of the clutch by optimizing the microstructure of the material. This is particularly important for clutch components that are subject to cyclic load changes, such as the release lever, which can effectively avoid fatigue fracture caused by long-term stress concentration and ensure the reliable operation of the clutch under various complex working conditions.

Heat treatment can also improve the thermal stability of the material, which is crucial for the working performance of the clutch in high temperature environments. By reducing the thermal expansion coefficient and improving thermal conductivity, the heat-treated components can better adapt to the high-temperature working environment, reduce the performance degradation caused by thermal deformation, and ensure the stable transmission efficiency of the clutch under high temperature conditions.

Although direct heat treatment does not directly affect the friction coefficient of the friction material, it indirectly optimizes the overall friction performance of the clutch by improving the hardness and wear resistance of the friction plate backing and pressure plate. A stable friction coefficient means a smoother engagement and disengagement process, reducing impact and noise, and improving driving comfort and safety.

As an enterprise with IATF16949 quality management system certification, our company's technical advantages in the field of clutch manufacturing are not only reflected in the heat treatment process, but also throughout every link from design to raw material procurement, mold making, heat treatment, surface treatment to final product testing. We have a professional testing center in the industry, equipped with advanced testing equipment from Germany, Switzerland, Italy and other countries to ensure that each batch of products can meet or even exceed industry standards and customer expectations.

The main components of the 430 pull-type clutch assembly have undergone a carefully designed heat treatment process, which not only significantly improves the product's wear resistance, fatigue resistance, thermal stability and friction performance, but also reflects our company's unremitting pursuit of technological innovation and its persistent commitment to high-quality products. We firmly believe that through continuous technological innovation and strict quality control, Ausde products will be able to better serve the global automotive industry and bring valuable product competitive advantages and quality assurance to every consumer.

English

English  No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, Čína.

No.25, Hu Chuang Road, New District Industrial Park, Suzhou, Jiangsu, Čína.  +86-13338663262

+86-13338663262